Strengths

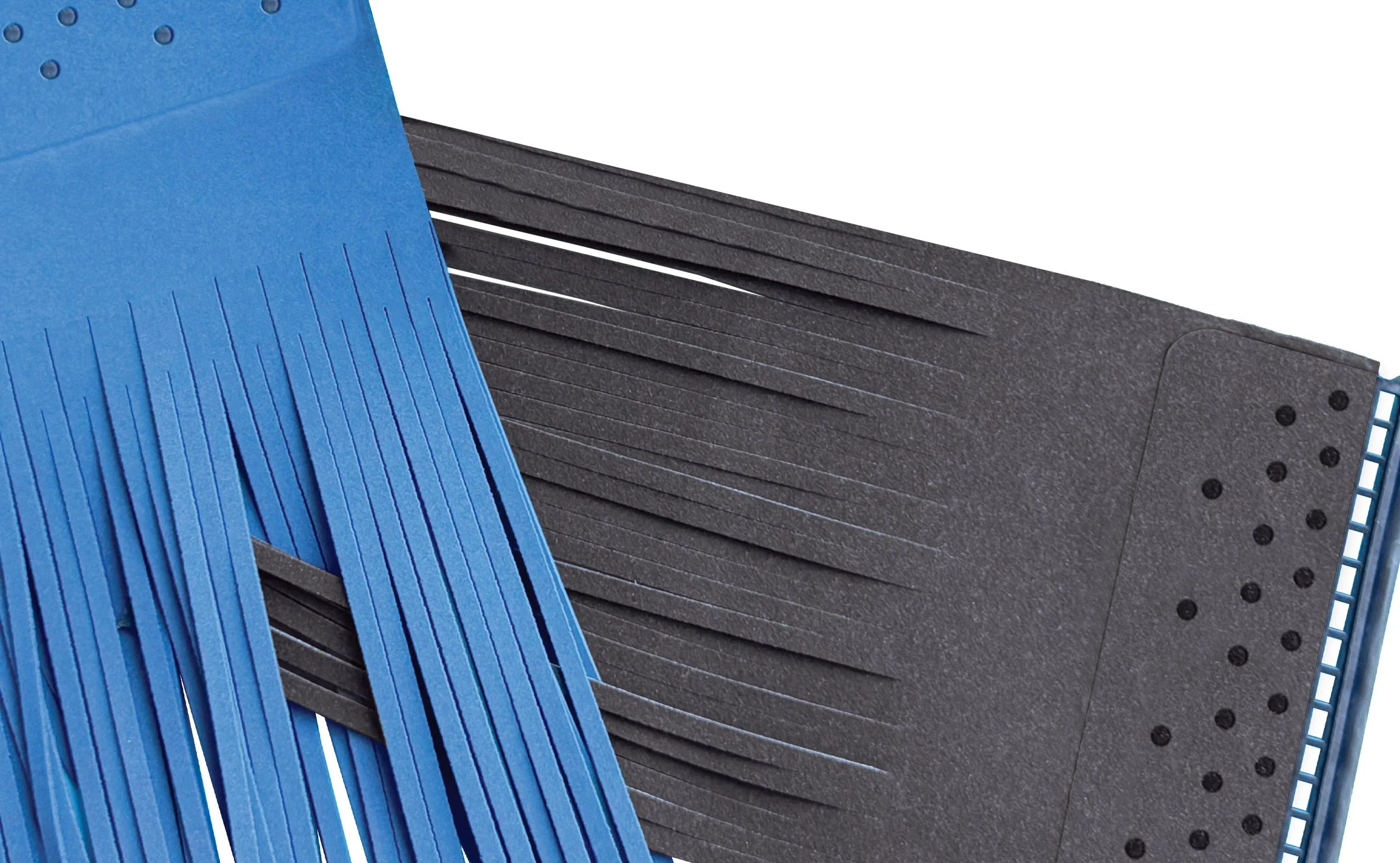

BRUSH BACKINGS

The supports are made of plastic material using Morelite’s proprietary designs and molds, at the company within our group specialized in injection molding. The coupling system to the brush holder tubes has been designed for quick assembly and maintenance through a mechanical sliding system within the grooves.

STRENGTH

The fastening of the material (foam, microfiber) to the support through injection molding ensures a strong and durable bond between the two parts, unlike traditional stitching methods.

FLEXIBILITY

Possibility to obtain strips of different heights according to customer specifications.

ADAPTABILITY

Compatible with any material (foam, lammscloth, microfiber, etc.).

Main features

-

The SLIDE system is an innovative mechanical coupling technology between the strip and the support, created through plastic injection co-molding. It eliminates the need for stitching or Velcro, providing greater strength, durability, and precision. In addition, it simplifies assembly and maintenance, reducing both time and operating costs.

-

Thanks to the versatility of the co-molding process, the SLIDE system allows the use of different materials such as foam, microfiber, and other technical fabrics. This makes it possible to customize the strips according to the specific needs of the system or customer, ensuring high performance and durability.

-

Yes. The SLIDE system includes adjustable injection molding, allowing the production of strips with variable heights adaptable to different configurations. This ensures each component can be custom-made, guaranteeing maximum efficiency and compatibility with any type of installation.

Colors

Richiedi Informazioni

Recensioni dei clienti

★★★★★

Una vera eccellenza sul territorio sammarinese. Complimenti

Un'azienda sorprendente per organizzazione ed automazione del lavoro! Leader nella produzione e progettazione di spazzole per autolavaggio.

+ Marco D.

★★★★★

Alta Qualità. Numeri uno

Ottima azienda leader nel settore della realizzazione e montaggio di spazzole industriali e per autolavaggio. Spazzole di qualità che durano nel tempo e garantiscono risultati eccellenti

+ Fabio C.