Strengths

SHAPE cut

An innovative cut that allows the bristled element, depending on its installation position, to follow the shape of the vehicle. A patented innovation that enables effective cleaning of upper glass sections, recessed areas caused by spoilers, protrusions, and unique exterior shapes—eliminating the need for additional brushes.

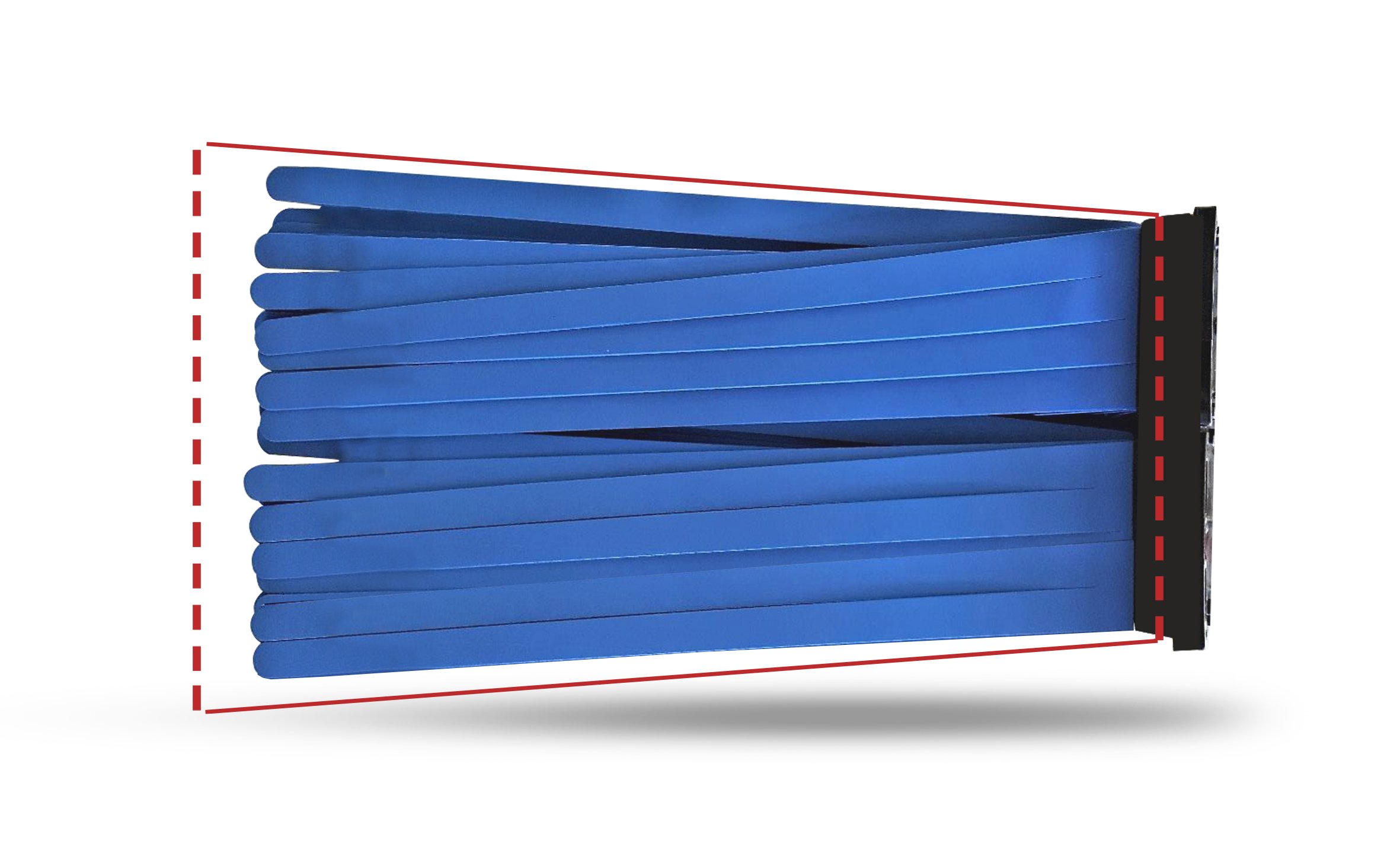

FULL TOUCH patent

Thanks to the innovations of the Full Touch patent, the offset positioning of the washing strips (traditionally anchored in parallel) causes the terminal part to widen, ensuring better contact with the surface being washed. Wind tunnel testing allowed us to determine the ideal cut of the washing strips, which now work side by side with no gaps between them. Moreover, the rounded root of each strip cut provides both a tear-resistant system and a smoother, more fluid movement of the washing fringe.

RADIUSING

The terminal part of the washing strip cuts is shaped like a tiny semicircle. This allows the strips to move more freely, improving performance and extending their lifespan.

Available colors

Available in 14 colors and an endless variety of combinations: single-color, sector, checkered, spiral, vertical bands, and more.

Customizations

During the strip cutting process, upon customer request, it is possible to personalize the strip by engraving a logo, code, or identification mark.

Quick coupling

The coupling system of the brush cores to the brush holder tubes has been designed for quick assembly and maintenance. In fact, thanks to the mechanical pressure interlock, no tools are required—except for a screwdriver. At the same time, it is highly durable, featuring both a pressure-fit core fastening and a mechanical screw attachment to the tubes.

Strips backings

The supports are made of plastic material using Morelite’s proprietary designs and molds, at the company within our group specialized in injection molding. An impeccable electronic welding process ensures that the strips, inserted into containment pockets that hold them in a radial position, become an integral part of the supporting structure for the entire lifespan of the brush, thus guaranteeing exceptional strength and durability.

Main features

-

Technology studied in the Wind Tunnel: the Full Touch Patent is a strategic cut of the sliding strips(traditionally anchored in parallel), which now work close to each other without gaps,

guaranteeing the enlargement of the end part and therefore better contact with the part to wash. -

Constantly oscillating brushes rub the vehicle in a cross direction, for total cleaning down to the

smallest detail and in less time. The strips are cut with two diameters such as to allow two movements (frictions) on the surface to be washed: one on the tip and one on the back. Combined with the rotation of the shaft in both directions, it allows for the simultaneous creation of two other movements (one upwards and the other downwards) for 4 total movements in a single brush which allows you to rub surfaces from multiple angles , ensuring an incomparable washing quality even in those areas of the vehicles where normal brushes cannot reach -

Unique of their kind, Morelite’s SHAPE® car wash brushes perfectly match the shapes of modern cars, even the most oval ones. SHAPE® rehabilitates the washing systems of a few years ago, born with brushes that do not tilt easily. The central part of the mop (the 3 central sectors) which touches first, takes command and sends signals to the processor to raise the horizontal. With the same reaction times, a SHAPE® mop is already working with 5 sectors: an advantage of 2 out of 3, almost 70% more!

Available colors

Request information

Customer reviews

★★★★★

A true excellence in the San Marino area. Well done

A surprising company for work organization and automation! Leader in the production and design of car wash brushes

+ Marco D.

★★★★★

High quality. Number one

Excellent leading company in the sector of construction and assembly of industrial brushes and for car washes. Quality brushes that last over time and guarantee excellent results

+ Fabio C.